Here’s a typical problem description for this particular failure:

sundevil6 wrote:

My Whirlpool Duet Sport washer won’t run. Washer has power and turns on. When I start it the door will lock and then nothing else will happen. Push cancel and the the add a garment light blinks and washer won’t do anything and the door stays locked. I have to unplug it to get control of the functions again. Went through codes and found 3 of the F21’s and one F26. Tried to run the diagnostic test but it will only lock door and the light blinks continually for the rinse/spin cycle and will not advance the test.

Replaced the door switch and still the same problem. I had the tech sheet and have already tried to run diagnostic test, and it tells me nothing. I had just cleaned the pump out a month ago and when I had the original drain problems the pump would run, but loud like it was cavitating. It did have alot of blockage in it then, but none now. The pump never even comes on when I try to start, nothing happens but the door locks.

Okay, this is an interesting one and illustrates an important point about error codes and how you can’t just blindly follow them.

According to the tech sheet for this washer (located inside the washer; get it by removing the front bottom panel), F26 is “Door Switch Error: If the door has not been opened for 3 consecutive cycles or the door switch is open while the door is locked for more than 5 seconds.” The tech sheet lists these possible causes and procedures:

■ Door not opened during 3 consecutive cycles.

1. Open and close the door.

2. Verify CCU operation by running a Diagnostic Test or any cycle.■ Door switch open while door is locked.

1. Push the door and check if it is completely closed.

2. Verify CCU operation by running a Diagnostic Test or any cycle.

Not very helpful and, as we’ll see shortly, not even close to the real problem with the machine.

F21 is the “Long Drain” error and this code could have been stored in the control from the pump problem that was fixed previously. Still not relevant to the present problem.

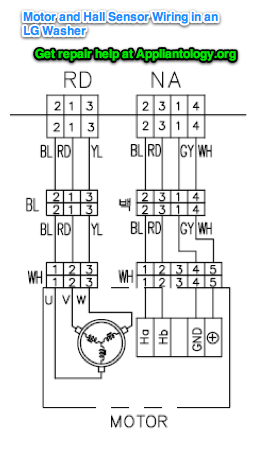

In any front load washer where the drum doesn’t tumble or spin, you want to keep in mind three key components in your troubleshooting: door latch assembly, motor, motor control board. Usually, the problem will be one of these three parts.

In this case, the door latch has already been replaced so scratch that one.

About the only way to test the motor is to measure the resistance of the motor windings and compare to the specification on the tech sheet.

And matt1 from the Samurai Appliance Repair Forums shares with us this technique for checking out the motor control board:

I’ve seen this problem before. Let’s do this:

– Get access to main control board.

– Find MS2 white connector with two pink wires.

– Use your volt meter to check the AC voltage supply to the board: power up then press Start.If you see 120 vac for a few seconds but the voltage drops back 0 vac, then you have a problem with motor control. On this model, if the drum won’t turn within a few seconds at start up, the unit will freeze and door will stay locked with no water coming in.

But wait! Don’t take my word for it: you can get access to motor control board from the back of the unit– it’s easier that way– remove the motor control board and do a visual inspection. Just looking at it from the outside, you will think there is not thing abnormal. But if you actually removed the board itself from the plastic casing and look on the back, you will notice the burnt mark on the three transistor area right away. You can purchase the motor control board from this web site. I hope this helps.

Part link for the Motor Control Unit ==> Click Here

If you’re still confoosed and need more free help fixing your washer, come start a new topic in the Laundry Forum at the Samurai Appliance Repair Forums and we’ll confoose you some mo’!

To learn more about your washing machine, or to order parts, click here.