Whirlpool Duet washer no-op & flashing SUDS, F35 error codes. This is user-inflicted damage, using non-HE detergent. http://ow.ly/2z3mh

Author Archives: Samurai Appliance Repair Man

Kenmore Laundry Appliances Will Connect for Remote Diagnosis

A new customer service technology, Kenmore Connect, enables some Kenmore and Kenmore Elite washers and dryers to communicate directly to service experts. The technology lets customers find out if their appliance is running correctly or receive instructions with a phone call and a push of a button. The system sends real-time diagnostic information from the appliance to service staff who can offer assistance and solutions to customers.

Kenmore’s field testing results showed a significant reduction in the need for in-home visits for customers who used the feature.

The appliances do not need to be hard-wired to send their information. To send information, the customer holds the phone mouthpiece over the appliance power button and press a button on the appliance to send the diagnostic data.

Service personnel can monitor more than 100 different data points to diagnose the unit and offer a solution. The data includes cycle and option settings, operational information (e.g., air/water temperature, estimated load size, spin speeds, fill/drain times, unbalanced load issues, etc.), details on the factors that contribute to the cycle time, status of certain electrical and mechanical sub-systems, and the mechanical issues associated with each error code.

This article gives the impression that Kenmore, a Sears marketing brand, is developing this technology in-house. I can guarantee you this isn’t the case. The Kenmore “factory” is a floor of offices on the Sears Tower where corporate suits make phone calls to other corporate suits who work for companies that really do make things, like Whirlpool or LG. No hints on who is providing this technology for Kenmore but I know for a fact that Whirlpool, Miele and most of the other manufacturers have already started implementing this feature in some of their models. Soon, as appliances become more computerized, they’ll all have it. Heck, they’ll *need* this feature just to be able to troubleshoot ’em!

But the real reason for all this connectivity is more insidious than just the gee-whiz factor or for diagnostic help. It’s also to make future appliances more compatible with– and controlled by– the coming Smart Grid. More on Big Brother’s Smart Grid here:

http://fixitnow.com/wp/2010/01/14/smart-grid-green-dream-or-just-another-big-brother-control-grid/

I don’t believe for a minute that the only data they’ll be sending is diagnostic info on the appliance. They’ll be collecting and sending all kinds of information; for example, how often you do laundry and is this “too often” (as determined by soon-to-be-announced government “standards”), are you using HE detergent, and are you using too much detergent. And just like it’s come out now that there are audio listening devices in your computer router, digital television set, and the NSA randomly listens in on your computer microphone and cell phone, you can be certain that this remote “diagnosis” will be yet another way for you to be surveilled.

But I’m not a big fan of all this computerization for another very practical reason: from a reliability standpoint, they SUCK! The electronics used in appliances are not near the robustness and quality of electronics used in cars, for instance. They fail at much higher frequency and at much greater expense than the simple, rugged mechanical controls they replaced. And let us not forget the 5th Law of the Prophecy: “Electronics and wet appliances do not mix.”

Can I hear an “Amen?”

Appliance War Story: Whirlpool-Kitchenaid (and some Kenmores) Dishwasher Not Draining; Bad Drain Pump

I was out swimming in Little Lake Sunapee with my Samurai Spudlets™ when the distress call came in on the Samurai Hotline™ on my waterproof iPhone™.

“Hello, Samurai?”

“Yes, ma’am,” I sputtered, as I spat lake water out of my mouth, “Samurai Appliance Repair Man™ here. How may I be of service to yo ace today?”

“Excuse me?” she axed.

“Why, what’d you do?” I wondered.

“Uhh… anyway, my dishwasher isn’t draining and it’s full of smelly water. And I’m having lots of people over for Labor Day weekend. Can you fix it before then?” she axed, plaintively, if not somewhat petulantly.

“Sho nuff, darlin’! I’ll be over before you can say, ‘Society is intrinsically a legal fiction says Foucault; however, according to Abian, it is not so much society that is intrinsically a legal fiction, but rather the fatal flaw, and subsequent absurdity, of society. But Bataille promotes the use of neodeconstructive desublimation to attack sexual identity. Marx uses the term ’submaterial capitalism’ to denote a textual totality.'”

[long pause]

“You still there?” I axed.

“Yes… I think. You’ve been here before. Just please come. And have the part.” *Click!*

“Well,” I thought to myself aloud, “that was rather abrupt. But, then, we do live up here in Yankeeland and people tend be no-nonsense and all-bidness thata way.”

“What was that, Dad?” one of my Samurai Spudlets™ axed.

“Nevermind,” I said, “I gotta go boyz; they’s a appliance in distress!”

So I did the ol’ Samurai Flutter Kick™ on the body board and cut a nifty V-wake back to the shore where I loaded up the truck and went to Bever-lee. Hills, that is… Oh, wait, wrong story.

Arriving at the customer’s house, still dripping with lake water on her tile floor, I went right to work on her misbehaving dishwasher. I opened the door and, Great Googely-Moogely!™, the smell about knocked my Samurai privates in the dirt! Sho nuff, that basin was full of skanky dishwasher water. I erped up some Foster’s Bitter and got down and dirty on that bad boy.

I ran it in drain mode and heard a gravelly noise coming from the drain pump. I removed the drain pump expecting to find a piece of gookus down there but it was clear. So I removed the drain pump and ran it and found the noise coming from the drain pump itself. Behold:

Classic bad pump motor. So I pulled a new drain pump off my service van, slapped that sucker in and no more dishpan hands for that customer!

And there was much rejoicing.

Here’s the part link for the new drain pump that I installed:

The Mysteries of Gas Dryer Bur…

The Mysteries of Gas Dryer Burner Components Revealed! http://flic.kr/p/nUViz

Daily Summary of Samurai’s Tweets, 2010-09-02

- Summer Haze Hangs on – Mt. Sunapee from the Clarke Lookout http://post.ly/v14J #

- Just another Samurai day at the office; I don't EVER wanna hear y'all complain about your working conditions! http://post.ly/v4jz #

- Bosch SHU99 Dishwasher With a Mystery Leak Underneath, Somewhere on the Right-Hand Side, Making the Pump Run Constantly http://ow.ly/2ycwT #

- Amana ALW480DAW washer: service manuals and tech sheets. Come and git 'em, Hoss! http://ow.ly/2ycDV #

- Evening dip with The Oz Man at Little Lake Sunapee http://post.ly/v6nY #

- Maytag Performa dryer chugging like a jackhammer. What part is most likely bad? http://ow.ly/2yfHq #

Follow me on Twitter to get all my Tweets as they happen:

http://twitter.com/FixitnowSamurai

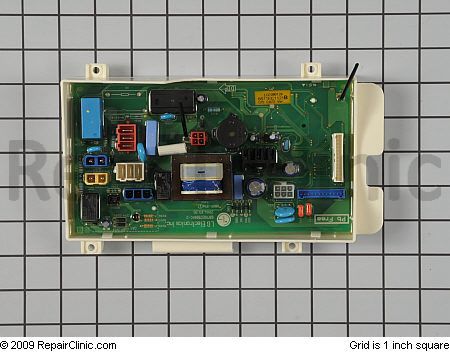

Troubleshooting an LG DLG5988W Gas Dryer that Won’t Dry; Proper Burner Sequence of Operation

Troubleshooting LG dryers can be a little daunting for those who are intimidated by electronic circuit boards. But this needn’t be the case. Despite all the fancy beep-beeps and whooplas, it’s still a gas dryer and the burner works the same way as any other gas dryer out there. In the Samurai Appliance Repair Forums, Sublime Master of Master of Appliantology john63 graciously offered this simple method of troubleshooting burner problems with LG gas dryers:

On a recent service call—I had an LG gas dryer with a *no heat* complaint—all components checked out fine.

As I was testing the NUMBER 2 gas valve coil for 90 volts from the MAIN BOARD (inserting the test meter leads into the gas valve coil plug) the gas burner began functioning.

The plug at the GAS VALVE COIL (there are two sets for coil no.1 and another for coil no.2) was not tight enough–in my case–the number 2 gas valve coil plug was too loose.

I removed both plugs from the gas coils and slightly bent the plug connectors on the gas valve coils. One slightly downward and the other slightly upward—reconnected the plugs–and the gas burner functioned perfectly.

This should be considered if the following test procedure does NOT identify a cause:

The correct sequence of operation for GAS HEAT operation is as follows:

1) FLAME SENSOR must be *closed* (closes at 320F/Opens at 370F)

2) COIL no. 01 is energized (90 VOLTS DC)

3) IGNITOR is energized & glows (120 volts)

4) FLAME SENSOR opens (370F) & IGNITOR begins to turn off

5) COIL no. 02 is energized (90 VOLTS )—Flame Ignites.If no power is measured at the gas valve coils (90 volts)–replace the MAIN BOARD.

Frigidaire Range Model FEF352A Parts and Wiring Diagrams

Frigidaire Range Model FEF352A Parts and Wiring Diagrams

Maytag Performa dryer chugging…

Maytag Performa dryer chugging like a jackhammer. What part is most likely bad? http://ow.ly/2yfHq

Evening dip with The Oz Man at…

Evening dip with The Oz Man at Little Lake Sunapee http://post.ly/v6nY

Amana ALW480DAW washer: servic…

Amana ALW480DAW washer: service manuals and tech sheets. Come and git ’em, Hoss! http://ow.ly/2ycDV

Bosch SHU99 Dishwasher With a Mystery Leak Underneath, Somewhere on the Right-Hand Side, Making the Pump Run Constantly

If you’re struggling with a mystery leak from you Bosch dishwasher and you can’t see from whence the leak doth originateth in accordance with the 7th Law of the Prophecy, then this harrowing tale from an intrepid Apprentice in the Samurai Appliance Repair Forums, Chesterfoxes, probably holds the answer. This particular war story was from a battle with a Bosch model SHU9915UC/U11 but the wisdom contained herein applies to all Bosch models from that era such as SHU43, SHU53, SHU68, SHI43, SHI53, SHI68, SHV43, SHV48, SHU33, and SHU99.

First and foremost, thanks for all the tips and hints from everyone – they were very helpful in getting this done.

Second, BLESSED IS THE MAN OR WOMAN WHO SERVICE THESE MACHINES, FOR THEY SHALL HAVE GERMAN ENGINEERS FOR SERVANTS WHEN THEY GET TO HEAVEN!

To anyone who has stumbled upon this post in an effort to solve their Bosch leak, I’ll give you what I’ve learned. Bear in mind that you’re machine is running onward forever as there is a float switch in the base that has been tripped (by leaking water) and thus puts the drain motor into continual operation.

1. Before doing anything (other then soak up the water in the base), remove the outer door shell and the panel at the bottom of the door – this will open up your field of view into the base. The outer door shell comes off when you remove the four screws on each side of the inside door rim. Then run the unit and see if you can visualize the leak.

2. If it’s the drain pump that leaks (or the water valve), you’re in luck because you can probably change it out without dropping out the base. If it’s one of the other gaskets (pump to sump or pump to heater) you’re basically screwed and are in for a long day. This is because you’ll have to drop the base to get to those components.

3. If you need to drop out the base, then first disconnect the unit from power and water and pull it out. Take out the drawers. Next, remove both side panels – held on by two screws in each side on the front vertical trim pieces on the front tub rim.

4. Remove the two screws in the back that hold the bottom tub onto the frame.

5. Lay the unit on it’s back. Remove the door springs from the base. Disconnect the ropes from the springs. Remove the screws in the front of the unit holding on the base. Take a few pictures of how the wiring is routed around the base. Unscrew the water valve and the electrical j-box from the base. Then pull the base off.

6. On my unit, both the pump to sump and pump to heater gaskets were damaged and leaking. This was probably due to the unit being laid on it’s side or upside down during shipping/installation (seven years ago) and one or both of the rubber motor suspenders became disconnected from their connecting posts on the base. This left the motor weight being either partly or entirely supported by the gaskets and likely led to their premature failure.

7. Oh yeah, great German design means that the pump to heater gasket is integral to the heater and you’re on the hook for an entire new heater. On the plus side, you get a new heater element, NTC, thermistor and flow sensor with the new assembly. You’ll need to order a new hose clamp for the gasket between the heater and the pump.

8. I rebuilt the pump with the kit that includes a new pump housing gasket and pump impeller. Impeller unscrews from the motor shaft – use a screwdriver jammed into the metal fan/cooling fins (at the other end of the motor) to stop the motor from spinning while you unscrew the impeller. Don’t be an idiot and nick the motor windings.

9. Install new door gaskets while you’re at it – not a big cost. My main door gasket was becoming gelantinous at the bottom corners. The bottom door gasket had a 1/4-inch of thick goo and two splits – definitely should be on anyone’s list while the machine is apart. The main door gasket just pulls out of its slot – jam the new one back in the slot. The bottom door gasket is a bit tricky – the end brackets for the seal are sandwiched between the door and the hinges. Only remove the lower of the two hinge screws – remove both and the door becomes uncontrollable. If you put the new bottom seal next the the old one (before you remove it) you’ll have a good idea of how to approach it.

10. Once I installed the new pump to sump gasket, the new heater assemply, and re-built pump, I suspended the motor from a piece of wood spanning the front of the machine until I got the base re-installed – it’s a lot of weight to be hanging on the sump and heater.

11. Don’t remove the sump from the tube unless you have to (see a leak?) – it’s a pain in the balls to get back in correctly.

12. Slide the base back onto the unit – don’t forget the rubber support that goes between the center of the sump and the base. Key item – get the rubber motor supports hooked back onto the two posts in the base.

13. There is a lot of work involved in putting the base back on – first, check to make sure the condensate drain pipe is routed throught the correct hole in the base. Second, make sure the water fill and drain apparatus (on the left side of the machine) is correctly together and in the right location. Next, make sure all the wiring is correctly routed – put the wiring connection blocks back into their holders on the base.

14. Before tilting the machine back up, re-install the door springs. This is a pain because without the springs, when you open the door the plastic connectors (at the opposite end of the ropes) likely came out of where they should be on the hinges. Also, the white plastic covers next to the hinges probably became dislodged. Check all this before hooking the ropes back up to the springs and re-installing them. Re-install the two front screws holding on the base to the frame. Tilt ‘er up!

15. Once you’ve tilted the machine back up, get back on you’re belly. First, make sure the rubber motor suspenders are hooked to the posts on the base. This is key. Then, check all the wiring routing to make sure it’s off the bottom of the base and also not laying on the water heater terminals. Check the water fill and drain mechanism (on the side of the machine) to make sure it’s seated in the correct position on the base and that they’re back together they way the started the day. Re-install the float and rod. Screw the water fill valve and j-box back into the basee. Re-install the two screws in the back of the machine to secure the base to the frame. Once you’re satisified all is good in the base, re-install the side panels.

16. Re-install the machine and run it. Make sure (visually) the leaks are gone and everything is good. Then reinstall the plate at the bottom of the door and the outer door panel. Find the kick plate (taken off weeks ago when it first started leaking) and put it back on.

All told, I replaced the two door gaskets, the drain pump, the heater, the pump to sump gasket, and re-built the pump. About $230 in parts. Never having done this before, it was a chore to figure it all out. It was probably a coin toss whether to fix the unit or replace it, but I’d probably rather fix it then throw it in a landfill. I put in enought parts that – knock on wood – it should be good for another seven years. However, if I had to pay someone to do this (no matter how good they were) I doubt that I could justify not going out and buying a new one.

Overall, the design is fairly slick – the bottom tub and flood sensor has probably saved the day more than a few times. It’s just awfully difficult to slide the base back on while making sure everything is back where it should be – I felt like I needed two more arms and hyperflex elbows.

A final thought – if only the pump to sump gasket is leaking, I’m not sure how you disassemble the unit to replace it without also getting into the heater to pump gasket. Is it possible to pull the pump out of the sump (to replace the pump to sump gasket) without pulling the pump off of the heater assembly? Probably not. Only problem is that the pump is held onto heater assembly gasket using a crimped-on hose clamp. How do you temporarily separate the pump from the heater assembly? I guess you could be clever enough to loosen the crimped on hose clamp. Maybe there is enough flex in the heater to pump gasket to allow you to pull the pump off of the sump.

A second final thought – why are the door gaskets (and others) turning waxy/greasy? I use regular diswasher detergent, no rinse aid, have a water neutralizer (not softener). Too much heat?

Hope this helps someone else – either to do it or to decide to call someone else to do it.

Can I hear an “A-freakin-men?”

Just another Samurai day at th…

Just another Samurai day at the office; I don’t EVER wanna hear y’all complain about your working conditions! http://post.ly/v4jz

Summer Haze Hangs on – Mt. Sun…

Summer Haze Hangs on – Mt. Sunapee from the Clarke Lookout http://post.ly/v14J

Daily Summary of Samurai’s Tweets, 2010-09-01

- Dirty electricity in your home harms your appliances *and* your body; now it's personal! http://post.ly/unIF #

- Skilled Workforce Shortage Threatens American Manufacturing – A Sinking Ship? http://post.ly/uoO1 #

- GE DBL333 dryer catches clothes and drags 'em around, defiling them with wrinkled brown marks. Horrors! http://ow.ly/2xIdJ #

Follow me on Twitter to get all my Tweets as they happen:

http://twitter.com/FixitnowSamurai

Frigidaire Electric Range Model FCS366ECF Wiring Diagram

Model Number Variations: FCS366ECF

Frigidaire Electric Range Model FCS366ECF Wiring Diagram