Here’s a handy pie chart that shows the most common expressions for Ohm’s Law. Very useful reference for things like common appliance problems and the Appliantologist Merit Exam. Handy and oh so expeditious!

Here’s a handy pie chart that shows the most common expressions for Ohm’s Law. Very useful reference for things like common appliance problems and the Appliantologist Merit Exam. Handy and oh so expeditious!

So, Grasshoppah, you think you’re smarter than the average grasshoppah? You think you got what it takes to be a Merit Apprentice Appliantologist? Or maybe even a Buckaroo Banzai Appliantologist? Well then, come strut yo’ stuff in the Master Appliantologist Merit Exam and we shall indeed see if’n you got what it takes to become one of the most fearsome and elite appliance repair shock troops the world has ever seen!

So, Grasshoppah, you think you’re smarter than the average grasshoppah? You think you got what it takes to be a Merit Apprentice Appliantologist? Or maybe even a Buckaroo Banzai Appliantologist? Well then, come strut yo’ stuff in the Master Appliantologist Merit Exam and we shall indeed see if’n you got what it takes to become one of the most fearsome and elite appliance repair shock troops the world has ever seen! ![]()

Keith wrote:

This is a weird gravity defying question for you folks & I tried searching but…… Today we have our washer on the 1st floor in the kitchen….we’re redoing the kitchen & the washer will join it’s sister in the basement… There is no plumbing the basement as the basement is well below grade. The main drain is ceiling height in the basement. 2 appliance “salesmen” have told me that the pump in the washer “should” be able to pump the water the 6 or so feet required to get it into the main drain tie-in. Does that make sense???? If not I’ve been told that I will have to install a laundry sink & then a small electric pump to make this work. Any thoughts?

Good question, thanks for axin’! Most washing machines made today, whether front loader or top loader, can pump out to a maximum height of eight feet. The stock drain hose that comes with the washer is only six feet long. So, in your situation, you’ll need to install a longer drain hose, like the one shown here.

You can also buy drain hose in bulk if you need something longer or more customizable.

As for the sink and sump pump situation, that’s pretty common in basement laundry installations. We had that same situation at our house before we moved our laundry upstairs outta the dungeon. This pump mounts to the bottom of your utility sink and pumps automatically as the need arises.

Tommy wrote:

I have a LSQ9544KT0 whrirl pool washer. I washed a load today wemt down 30 mins later the wsher was full of water. it would not drain out, I messed with the nob when I put on wash the wash gator would turn when it came time for the water to start drainin out I could here like a clicking nosie on the main switch. do you have any Ideals thank you for your time

One of my highest Ideals is to use a spell chekr on everthg I wright. And I like to re-reed it to re-reed it to make sure I catch composition problems when I re-read it. Especially if I’m emailing someone for free advice. ![]()

If your refrigerator is warming up and it makes a noise like the one here… (wait for it, wait for it…)

… then you need to unplug the refrigerator immediately before you do some real damage.

Chances are that the noise featured in the video is caused by a bad start relay on the compressor— a simple control repair. But if’n you let the compressor keep trying to start, you’ll fry that sucker like a deep fried rat.

Yep, each time you hear that low hum when the compressor is trying to start, the compressor is sucking an ocean of electricity and gettin’ reeeel hot. Eventually, the insulation over the motor windings breaks down. Once this happens, the compressor won’t start even if you do replace the start relay; nawsir, it’s what we professionals call FUBAR.

Replacing a compressor is an expensive job that requires lots of special tools and training.

OTOH, you can replace a compressor start relay with a screwdriver and needle nose pliers.

So, listen up!

To learn more about your refrigerator, or to order parts, click here.

Call 526-7129

If you live in the New London, New Hampshire area, and you need a major kitchen or laundry appliance repaired, call The Appliance Guru for service so good it’s beyond exceptional– it’s sublime!

The Appliance Guru provides prompt, convenient service in the following towns in New Hampshire: New London, Elkins, Wilmot, Springfield, Georges Mills, Sunapee, Mt. Sunapee, Newbury, Sutton, Bradford, Warner, Grantham, and the Eastman Community.

Or, use this nifty form and I’ll reply ASAP:

So your dryer shat the bed. Now the horns of an enema confront you: spend the yen to repair your energy hog clothes dryer or buy another keg of Old Milwaukee. Yeah, life is full of tough choices like that. Well, Hoss, tell you what I’d do: I’d scrap all the old parts out of that broken dryer and sell ’em on eBay. Then, with some o’ dat dinero I made on eBay, I’d git me a slick new High & Dry and never have to worry about a broken dryer again!

For more information about the revolutionary new High & Dry, send an email to Talia at highanddry@wildblue.net.

Friggidaire washer

Friggidaire washer

E47, no spin.

Replace the door lock.

![]()

To learn more about your washing machine, or to order parts, click here.

The GE Arctica and Profile line of refrigerators use an actual compooter muthaboard. It’s like the one in your PC or Mac except not nearly as durable. Like most of the cheesy electronics used in appliances, this muthaboard fails frequently and is expensive to replace. There was a rash of these problems a few years back. Still a common problem today.

Why did I buy a refrigerator with a muthaboard?

Beats me. I’m still trying to figger out why you even *need* a muthaboard in a refrigerator.

What kinds of problems with my refrigerator may indicate a bad muthaboard?

What has GE done about this to take care of their customers, mainly me?

Well, they wrote this reel nize concession letter.

How’s a wide-eyed grasshoppah supposed to know how to replace the muthaboard?

You’re not, that’s why it comes with instructions.

Is there anything I can do to extend the life of the muthaboard?

Use a surge suppressor with all your electronified appliances.

Where’s the best place to buy the new muthaboard?

Ahh, Grasshoppah, you have saved the best question for last! Come git you one.

To learn more about your refrigerator, or to order parts, click here.

You can usually tell you’re dealing with one of these puffed-up beasts (also sold under the Kenwhore label) because it’ll have the words “Even Heat” somewhere on the control panel. This dryer is a perfect example of how buying appliances with needless and overblown electronics is hazardous to your financial health.

So, my brothers and sisters, let us begin today’s sermon with a plaintive plea for sanity from another one of my sermons:

Dryers are simple, humble machines that do three things: tumble the clothes, get ‘em warm, and move a lot of air. Why would you want or even need an over-priced failure-prone “electronic control system” for a friggin’ dryer? I can almost understand it for a refrigerator or a gourmet oven, but a dryer? Putting an electronic control board in a dryer is like installing a GPS nav system on a kid’s tricycle. Enough! Stop the madness! Friends don’t let friends buy dryers loaded with over-blown electronic crap.

In today’s sermon, I’ll ‘splain easy fixes for two common problems with this needlessly electronified dryer:

Both problems, by the way, are a direct result of using an electronic control board and chintzy relays instead of a reliable mechanical timer and simple, rugged mechanical switches.

So, as you expect, most of the time the problem is going to be either the Even Heat control board or the motor/heater relay (there are separate relays for motor and heater but they are the exact same part).

We’ll start by opening up the control panel so we can make some simple electrical tests. Unplug the dryer and remove the two screws on either side of the console and flip the console back so it’s all opened up like ahso (click for larger view):

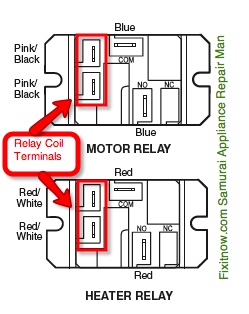

And here’s a pictorial diagram of what you’ll see (click for larger view):

Now, start with a visual inspection. If the Even Heat board is the problem, you may see a burnt component on it, like this (click for larger view):

But remember that electronic boards can- and commonly do– fail without any visible signs of failure. So just because an electronic board may appear okay, this does not mean that it IS okay. Otay, Buh’wheat?

Anyway, a few simple electrical measurements at the relays will usually tell the story. Here’s a closeup of the relays:

The relay coils are outlined in red. A good coil will have a resistance in the range of 2 to 3 k-ohms; a bad coil will either read infinite resistance or something in the mega-ohm range.

The Even Heat control board sends 48 vdc to the relay coil to close the switch in the relay output. When the relay switch closes, it sends power to either the motor (in the case of the motor relay) or to the heating element/gas burner assembly (in the case of the heater relay).

Armed with this knowledge, you can determine whether the Even Heat control board or the relay itself is causing the problem by doing exactly two simple tests on the appropriate relay. Let’s break it out by type of problem.

Test 1: Measure the coil resistance on the heater relay. Remember: resistance measurements are made with power off the circuit, so unplug the dryer for this test. If the heater relay coil is open or very high resistance, replace the relay.

Test 2: If the relay coil tests good, then we check for 48 vdc (that’s volts-DC– double check your meter setting when you measure for this) at the relay coil. This is done with the dryer running on a heated dry cycle and all the wires still attached to the relay. If you don’t get 48 vdc at the relay coil, replace the Even Heat control board.

But what if you do get 48 vdc at the relay coil but still no heat? Then we may have a problem elsewhere in the heater. We can confirm this by verifying that the relay is closing its contacts when the coil gets voltage with another live test. Again, dryer running in a heated dry cycle, set your meter for the 120vac range and measure the voltage across the relay contact terminals (the ones with the heavy red wires attached to ’em). If no voltage reading, that means the contacts are closed and the relay is doing its job; so the heating problem lies downstream in the heating circuit. We can help you troubleshoot this in the Samurai Appliance Repair Forum.

Same two tests as for the heating problem above except you do all the tests on the motor relay. That makes for a nice and easy symmetry, don’t it?

If you get 48vdc at the motor relay coil but still the motor doesn’t run, then we have a problem downstream in the motor circuit to troubleshoot. Again, we can help you with this in the Samurai Appliance Repair Forum.

Can I hear an “Amen?”

To learn more about your dryer, or to order parts, click here.