Some good info in this topic at the Samurai School of Appliantology for buying and using front load washers. If you’re shopping for one or a current owner/user of one, it’d be worth taking a couple minutes to scan thru it.

Category Archives: Washer Repair

Auto Load Detection in Newer Model Whirlpool (and some Kenmore) Top Loaders; We’re Not in Kansas Anymore, Toto!

Newer model Whirlpool-built (includes Maytag brand and some Kenmores) top loading washers are using a newfangled technology called “auto load detection.” Whirlpool washers with model numbers like WTW57ESVW0 and Maytag washers with model numbers like MVWC6ESWW0 use this new system.

Auto load detection senses the load of clothes in the tub and automagically provides the correct amount of water to get ’em washed. It works with a flow meter and an automatic temperature control (ATC) switch, both also new, to accomplish this miracle of modern engineering.

This is all done as a band-aid attempt to reduce the obscene amounts of water used by these dinosaur top-loading washers. Of course, if you, as the green-minded and environmentally conscientious consumer, were truly concerned about conserving water, you wouldn’t be using one of these machines in the first place; you’d use a front loader or one of the high-efficiency top-loaders. But I digress…

As far as band-aid hacks go, this one has been pretty reliable. When something does go horribly wrong, one of the most common problems you’ll see is that the washer will start agitating as soon as it starts filling with water when you start the machine. It may also start filling during the spin cycle with the end result of your clothes coming out sopping wet. How’s that for water conservation?

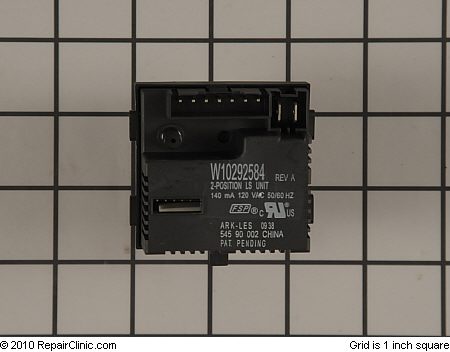

If you see this problem, the cause is almost always a bad water level (load sensor) switch. It lives in the control console and looks like this:

You should be aware that Whirlpool uses at least two variations of the auto load detection switch so be sure to look up the correct switch for your washer using your model number. Just get your model number and plop it into this nifty search box and you’ll be sure to get the right switch (or any other part you need):

In case you want to know more about the new auto load detection system, here’s the tech bulletin from Whirlpool:

Auto Load Detection in Whirlpool-built Top-loading Washers

To learn more about your washing machine, or to order parts, click here.

The sound of bad drum bearings in a front loading washer; if your washer sounds like this, you’re goin’ shopping.

Awwite, grasshoppers, y’all go grab you a brewski and weird ol’ Uncle Samurai’s gonna tell ya a sorrowful tale of a heartbreak service call on a Kenmore (Frigidaire) front load washer.

Went out on a service call the other day on one of these machines. Complaint was that the washer was full of water, wouldn’t pump out and wouldn’t spin.

Well, this is a pretty common problem with any front loader– no pumpy-outy, no spinny– and you usually end up finding some piece of gookus, like a nail or a piece of plastic, caught in the pump impeller. I’ve previously posted a nice, commented set of photos detailing this repair that you can peruse here:

Frigidaire Front-Load Washer Drain Pump Clean-Out

So I whipped out my katana and prepared to deal harshly with this washer’s major malfunction. The katana in this case was my wet vac that I needed to use to suck the water out of the drum cuz if’n you don’t do that first, you’ll have one helluva mess when you pull off the pump suction hose.

With as much water sucked out of the drum as I could get, I then removed the suction and discharge hoses from the pump and unscrewed it so I could pull it out and feast my bloodshot Samurai peepers™ inside that thang (see the aforementioned photo album link for details on this). With the pump removed, I turned that sucker around and, lo, I did behold the offending item:

That’s a pretty hefty and unusual piece of plastic broken off from somewhars and caught in the pump impeller and it looked uncannily like the same material as the drum, same color, same heft. Somewhere, deep in the murky, fermented recesses of my solid steel Samurai cerebrum, something was nagging at me saying, “Yo, Samurai, sumpin’ ain’t raht.” But I shook it off and proceeded to put it all back together.

After I got it all put back together, I fired that puppy up and prepared to bask in the glory and accolades of having spared another household from a trip to the Laundromat. The machine filled with water and pumped out just fine. But when it ramped up to high speed spin, my bowels got all loose and quivery-like when I heard this noise:

In this next video, you can hear it winding down from high speed spin as the inner basket comes to stop and the chattering noise subsides:

Then came the sinking, sickening horror of realizing that all my foregoing sweat and labor on this washer was for naught. This is the sound of classic drum bearing failure in these washers. If your washer sounds like this, you’re going shopping. The new bearings come factory-pressed into the drum assembly and the cost of the parts alone is over $400. And it’s a complete teardown; a three-hour job that’s best done with two men; not worth the money and I advised the customer accordingly.

In discussing it with the customer, she told me that the washer was making that same loud noise right before it quit running. Then it all came to me in a vision.

I realized that the odd piece of plastic caught in the pump impeller was a broken off piece from the drum. I looked but didn’t find a hole broken through the drum so it must have been an inside piece of the drum that got broken off from the inner basket banging around inside there during high-speed spin.

The moral of the story? Well, there are two:

1) when you see a heavy-duty piece of plastic that looks suspiciously like the drum caught in the pump, stop and ask the customer if the washer was making an unusually loud racket before it stopped running, and

2) some days, I’d rather be licking urinals at the Texaco than running appliance service calls.

To learn more about your washing machine, or to order parts, click here.

Whirlpool Duet washer– push the power button, beeps 3 times but won’t run: the short and shorter solutions

Example model number: WFW9200SQ02

Short answer: Common problem and the solution is to replace the Motor Control Board (MCU):

http://www.repairclinic.com/SSPartDetail.aspx?s=t-WFW9200SQ02-%3d%3dc13i1257029&PartID=1257029

Longer answer but still mercifully short:

I’ve posted about a very similar problem to this one except with the display showing the F70 error code. Same diagnostic procedure and solution described in that post would apply. Come hither:

To learn more about your washing machine, or to order parts, click here.

GE Washer Model WCSR4170G2WW Wiring Diagram

GE Washer Model WCSR4170G2WW Wiring Diagram

Model number variations: WCSR4170G2

To learn more about your washing machine, or to order parts, click here.

Maytag MAVT446 washer with a melted motor pulley

The Quandary: Is it really just as simple as replacing the pulley or does a deeper, darker, more insidious problem lurk deep within the bowels of this beast?

Nah, just replace the cheesy pulley. It’s just a freakin’ piece of plastic, whaddya expect?

Pulley part link: http://www.repairclinic.com/SSPartDetail.aspx?s=t-21001108-%3d%3di1472&PartID=1472

To learn more about your washing machine, or to order parts, click here.

GE front load washer models GBVH WBVH WCVH WHDV 5000-6000 schematic diagram

GE front load washer models GBVH WBVH WCVH WHDV 5000-6000 schematic diagram

To learn more about your washing machine, or to order parts, click here.

GE washer model WDSR2080D5WW Schematic

GE washer model WDSR2080D5WW Schematic

Model number variations: WDSR2080D5, WDSR2080

To learn more about your washing machine, or to order parts, click here.

Maytag Atlantis washer quick transmission diagnosis tip: if the agitator is going back and forth while the basket is spinning, the transmission is toast

Example model number: MAV7700AWW.

The agitator may be doing one of those lazy numbers where it’s still going back and forth but slower than it does during the normal agitate cycle. Doesn’t matter; if the agitator is working at all during the spin cycle, then the transmission is toast, fried, smoked, FUBAR. The gears inside this transmission are all plastic. This is what we’ve come down to: cheap plastic crap not made to last but made to be repaired every few years or, what they really want, throw it away and buy a new one.

Anyway, if you’re married to this washer and want to replace the transmission, be my guest; here’s the part link to the transmission:

http://www.repairclinic.com/SSPartDetail.aspx?s=t-MAV7700AWW-%3d%3dc25i1472816&PartID=1472816

Frigidaire ATF6000FS0 front lo…

Frigidaire ATF6000FS0 front load washer sometimes stops mid-cycle & throws E52 error code. Diagnose in 2 easy steps. http://j.mp/bxrze9

Whirlpool top-loading washer w…

Whirlpool top-loading washer with auto load detection (eg., WTW57ESVW0); the top three most common problems http://j.mp/bRZvuR

Whirlpool/Kenmore Cabrio and Maytag Bravo washers throwing the vexing “oL” error code, even when unloaded

The “oL” error code in the Cabrio and Bravo washers means the motor is sensing an overload (“oL”) condition. While this could indicate a problem with the motor, it usually doesn’t. Most of the time, you’ll see this error code when one of two things is going on:

1) There’s a piece of clothing stuck between the inner basket and outer tub.

2) The tub is not floating freely, usually because it’s seized to the drive shaft by rust and crudus; FYI: this condition is almost always caused by using non-HE detergent in this washer– see this post for more info about using non-HE detergents in these high efficiency washing machines. Also, be aware that, if this is the case, it can be very difficult to remove the basket from a badly corroded drive shaft, could even be a two-man job. And be careful you don’t wrench your back!

In either case, you’re gonna need to do some tear-down to remove the inner basket. This video will help you with that.

To learn more about your washer or to order parts, click here.

Rebuilding the transmission in…

Rebuilding the transmission in an old Maytag top-loader. Is it worth the trouble in these old washers? You betcha! http://j.mp/dwOn6Y

Maytag Atlantis washer won’t f…

Maytag Atlantis washer won’t fill; replaced inlet valve, same deal. What’s the prob? Answer might surprise you! http://j.mp/d98BRs

Diagnosing the Mysterious and Elusive “te” Error Code in LG Washing Machines

According to LG’s service information, the pernicious “te” error code is caused by a faulty thermistor. If you were just blithely to go buy a new thermistor and plug it in hoping to fix your washer, you may be disappointed. Sublime Master john63 honors us again in the Samurai School of Appliantology with his pearls of wisdom on this vexing error code:

THERMISTORS rarely fail in LG washers.

The most likey cause of the “te” error is:

1) Loose wiring at the control panel (directly behind the CYCLE SELECTOR KNOB)

2) Broken wire at the THERMISTOR (located at the bottom /front of the tub)

To access the wire plug connectors at the CONTROL PANEL—-remove the top cover of the washer.

Stand in front of the washer and look for the plug connectors behind the CONTROL PANEL. Pull apart the plugs and re-install.

Test the washer. If the “te” error still occurs—-it will be neccesary to remove the FRONT PANEL as well (two sets of special plier-type tools are needed).

Inspect the THERMISTOR closely—-with good lighting. If there’s a break in the wire it will be at or near the black sheathing / heat shrink material.

Though not as common—-a broken wire at this location is *usually* caused by excessive vibration during the spin cycle. This is also *usually* found on the older LG washers that are in *wood floor* laundry rooms.