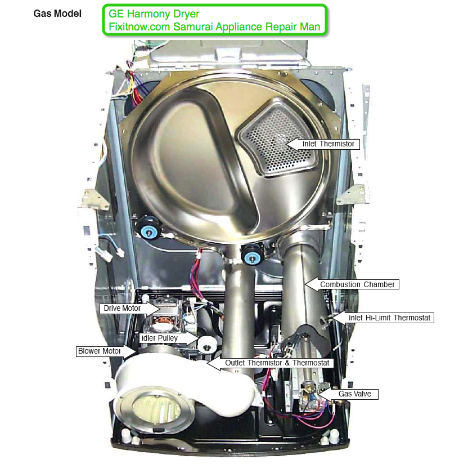

(Click the pictures for the larger versions with enlightening annotations.)

New-Style (crappy) Idler Slider Pulley that came with the Dryer

New-Style (crappy) Idler Slider Pulley that came with the Dryer

Some genius at Whirlpool figured out how to save $0.12/dryer by using the infamous half-moon slider idler. The belt slides across the teflon strip causing accelerated belt wear and much more frequent belt replacements. The extra strain on the motor has caused premature motor failures, too. Good for me because I fix ’em for a living; bad for you because you’re paying for it! Note the black fuzz below and beside the motor. That’s from the belt.

Close up of the Crappy Idler Pulley

Close up of the Crappy Idler Pulley

Yep, that’s all there is to it. No roller, just a teflon strip. The belt rubbing across this teflon strip can make weird noises, too. That’s what prompted the customer to call me in the first place.

Old-Style Roller Idler Pulley Installed

Old-Style Roller Idler Pulley Installed

Here, I replaced the slider with the old-style roller idler pulley. Whirlpool has since discontinued the slider style because of all the premature belt failures out in the field. Experience is the price of wisdom. Can I hear an "Amen?"

If your Whirlpool-built dryer (which includes many Kenmore dryers) has the troublesome slider pulley, replace it today with the good ol’ roller style and save yourself some big $$ down the road. You can replace just the idler pulley alone or, for a just few more shekels, you can get the complete repair kit which includes the roller-style idler, belt, and both drum rollers. Parts links below:

Idler Pulley Only

Complete Repair Kit

Related Helps:

Dryer Disassembly

How Does that Dryer Belt Go On?

To learn more about your dryer, or to order parts, click here.

![]()

![]()