This washer is an oldie but goodie, manufactured by Maytag back in the days when Maytag earned a reputation for quality and dependability (unlike the junk being cranked out today with a Maytag label on it).

You may be thinking, “Oh, but it’s so old, I’ll just buy a new washer and get another 20 years out of it.” Oh, feckless grasshopper, you would be in for a rude awakening.

I. Essential Tools

II. Required Parts

III. The Procedure

1. Unplug washer and Remove two Philips head screws holding front panel in ( newer models have clips on the bottom and no screws )

2. Remove front panel, lift panel from sides, has two “tabs” on top

3. Remove two 3/8ths hex head screws holding top down

4. Lift up top, it’s somewhat hinged, careful lid doesn’t smash against wall or pipes

5. Disconnect water tube on left side to top cover

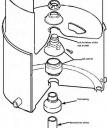

6. loosen the two screws on the steel band… straight or 5/16th ( newer washers have a plastic tank cover, pry out the tabs and lift up to remove the plastic tank cover )

7. gently but forcefully remove the top cover

8. careful not to bend the band or cut the gasket

9. *remove the agitator by grasping firmly and pulling up towards your chin, carefully!

*( many have 1/4 hex head screw on agitator, down the side near the base, older ones have a rubber ring on transmission shaft )

10.using a hammer and your spanner wrench remove or cut off the spanner nut, it is a left hand thread so it must come off clockwise, careful not to chip the tub

11. remove the inner tub,, it’s heavy with the concrete counter balance

12. take the Allen wrench screw (or torx) out of the mount stem ( see one of the 4 dimples for the set screw )

13. using your hammer and spanner wrench take the mount stem off, mount stem is a left hand thread so it must come off clockwise

14. now grasp the seal and remove, careful you can slip

15. put a 1/2″ socket on the nut on the front and 1/2″ box wrench or adjustable wrench on the inside bolt, and loosen using the socket on the outside, but not remove entirely the front nut

16. then using the same two tools remove the left and right bolts and nuts and lock nuts and plate, noticing the fiber washer

17. then remove the front one

18. remove tub to pump top hose clamp and pull off up 1/2 of that hose, now work the outer tub loose and lift up but not out entirely

19. remove the pressure hose on your rear right side

20. take out the tub

21. stomp (using your foot) out the tub bearing housing from inside the outer tub

22. remove the “metal sleeve collar” on the transmission shaft

22A. you’re half started

23. turn the outer drum over

24. take the new tub bearing and “stomp” it into the outer tank…flush, take your time and double/triple check yourself on these steps, (takes less time to recheck and verify than to tear down and start over)

25. put the new collar over the transmission

26. put the outer tub back on and reattach the pressure hose and pump hose

27. line up the front hole and put the front (short) bolt in, making sure you have the fiber washer on the outside of the tub

28. put the rectangular flat washer on, then the lock washer and the nut by hand…

thread it on a couple of turns but leave loose

29. put the right and left bolts and stuff on, tighten well

30. tighten up the front one

31. Put the seal on next, careful not to tear the seal, but it needs to be all the way down. One side has a special edge of carbon or something like that and that needs to be UP towards you. Sometimes taking a little bit of liquid laundry detergent and lining the inside bottom lip of the seal with it can help with the installation of the seal onto the tank.

32. take the torx screw out of the new mount stem, and screw down the stem mount, tighten with spanner wrench ( don’t over tighten! ), install the torx screw

33. put the inner tub on

34. check the spacing around the top of the inner tub (making sure that the tub is not listing one way or another)

35. put the metal cover on and spanner nut

36. put the top cover on and push it all the way down

37. check and clean the gasket and put it back on

38. put the clamp back on over the gasket

39. tighten to a moderately firm but not tight setting

40. carefully with a long straight screwdriver pry up the top part, bit by bit

run your fingers around the clamp to make sure the gasket didn’t pop up

41. when you think you have a good position, take your index finger and on the inside put it between the top cover and top of the inner basket and make sure you have this space all round so that the inner basket doesn’t rub against the top cover

42. tighten the clamp

43. reinstall the hose from the injector to the top cover

44. plug unit back in and turn to spin

45. let it spin for a couple of minutes

46. turn timer to fill and put water in

47. water test before securing top and reinstalling front panel