CDC Warning: ***DO NOT DO THIS!!!***

CDC Warning: ***DO NOT DO THIS!!!***

(You can click the photos for a larger view. Or not. Whatever.)

It’s kinda like porno. Not that I’d know anything about that. Por-who?

I have to cut that cap off so I can make the connection with the hand shut off valve using the pipe glue. Uhhh… forgot whether or not I shut off the water before I cut that cap off. Well, I reckon we’ll find out.

Hi. Welcome to my world.

Holy guacamole, Batman, it works! Connection made and water pressure turned back on. No torch, just this glue holding the water valve to the copper pipe. Sheer and uttah, uttah madness!

An art shot. Go "ooh! ahh!" or something.

You’ll probably need to take apart and tape all the connections right under the sink. If’n you need to, you’ll know as soon as you restore water pressure.

Dayyam! I should be a water valve photographer…. or something!

The bathroom sink installation: plumbing. Fini.

WARNING: The Department of Defense has classified the Supah Samurai Search (SSS) an appliance repair weapon of mass construction. This search engine is considered to be the nuclear bomb of DIY appliance repair. Use of the SSS may result in your appliance not being broken any more.

The scope of the Supah Samurai Search (SSS) includes the thousands of appliance repair articles I’ve written here at this site plus the hundreds of thousands of pages of specific, topical appliance repair discussions at the world-famous Samurai School of Appliantology. If you think you have what it takes to handle this quantum flow of information, then click the hyperportal image below to engage the Supah Samurai Search…

Re-thinking this weekly-summary-of-tweets-on-my-blog bidness. Messy-looking and insufficient granularity for search. FNO: 1 post/tweet.

Just when it looked like my rehab was going so well, I had a relapse and produced the most important newsletter in history! Thank you for not asking which history this newsletter is important to but, if you must know, it’s the history of Applianchia, a remote, mountainous region in Lower Slabovia famous for producing the appliance repair nephilim of yore. Those nephilim can be greedy, too, so hurry and get your FREE copy of the latest newsletter before they snarf it all up!

Just when it looked like my rehab was going so well, I had a relapse and produced the most important newsletter in history! Thank you for not asking which history this newsletter is important to but, if you must know, it’s the history of Applianchia, a remote, mountainous region in Lower Slabovia famous for producing the appliance repair nephilim of yore. Those nephilim can be greedy, too, so hurry and get your FREE copy of the latest newsletter before they snarf it all up!

And if, in the future, you’d like your very own personal copy of Appliantology sent to your email in a discreet brown wrapper so the appliance nephilim don’t git it first, kommen zie hither, bitte.

Sherry wrote:

Duet washer:

Problem– control is locked.

Solution– all the way to the right of panel, push & hold “end of cycle” for 3 seconds(It’s actually written beneath button).

Domo, Sherry! And lots more appliance repair revelations on the Duet washer ratcheer.

To learn more about your washing machine, or to order parts, click here.

Get these Appliance Repair Tweets real-time as they happen– follow me on Twitter.

Get these Appliance Repair Tweets real-time as they happen– follow me on Twitter.

Front-Loading washer,

Front-Loading washer,

drain pump hummms but will not drain.

Gookus stuck in pump.

![]()

To learn more about your washing machine, or to order parts, click here.

Started a new forum at the Samurai Appliance Repair Forums for TOOLS. It’s called The Tool Box. This is such an obvious forum to include; I don’t know why I didn’t think of it earlier! Must be all that cold mountain air freezing my brain.

Anyway, this forum is all about tool talk for tool heads and cool tools for fixit fools. Found a cool tool you want to share? Or made a tool for a specific repair? Well, come tell us about it. Also, specialty tools for appliance repair and tool recommendations from Master Appliantologists. Come rumble in The Tool Box.

This Pearl of Appliantological Wisdom℠ applies to the Maytag and Jenn-Air side-by-side and wide-by-side refrigerators manufactured in 2001. (How do you know what year your refrigerator was manufactured? Consult The Oracle!) The problem here is that the freezer gets goodncold (that’s a technical term used by us professionals, defined as 0°F or colder) but the all-holy beer compartment (that’s the one that ain’t the freezer, kapeesh?) won’t get below 40°F, or so– certainly not cold enough for any self-respecting lager drinker. We gotta step through the paces on this one so grab ‘hold of your favorite katana and let’s romp.

First order of bidness is to get some hard numbers on the temperatures in both the freezer and beer compartments. If you don’t already, you should have two thermometers specially made for refrigerators living inside your fridge, one in the freezer section and another in the beer section.

First order of bidness is to get some hard numbers on the temperatures in both the freezer and beer compartments. If you don’t already, you should have two thermometers specially made for refrigerators living inside your fridge, one in the freezer section and another in the beer section.

“But, Samurai, I know my freezer is cold because the ice cubes haven’t melted. So why do I need to spend money on thermometers?”

Ahh, Grasshoppah, do you have a calibrated palm that can tell the difference between 0°F and 17°F? No? Well, there ya go. A good freezer will easily keep 0°F and indicates that all is well with the sealed system and condenser fan. OTOH, if your freezer has trouble getting much below 20°F or even 10°F, then, Houston, we have a situation– see this page for further guidance. In a freezer at 0°F, the frost pattern on the evaporator (the coils inside the freezer– hidden behind a panel– that make all the cold air for the entire refrigerator) will look something like what’s shown here. Notice how there’s a thin, fine layer of frost evenly distributed over most of the coil as opposed to too much or none at all.

Ahh, Grasshoppah, do you have a calibrated palm that can tell the difference between 0°F and 17°F? No? Well, there ya go. A good freezer will easily keep 0°F and indicates that all is well with the sealed system and condenser fan. OTOH, if your freezer has trouble getting much below 20°F or even 10°F, then, Houston, we have a situation– see this page for further guidance. In a freezer at 0°F, the frost pattern on the evaporator (the coils inside the freezer– hidden behind a panel– that make all the cold air for the entire refrigerator) will look something like what’s shown here. Notice how there’s a thin, fine layer of frost evenly distributed over most of the coil as opposed to too much or none at all.

Still here? OK, that means everything I’ve talked about so far checks out on your fridge and you are now ready to learn the advanced repair kata for this problem. All is revealed in this parchment from the Appliantology scriptures.

Now go kick some refrigerator butt!

To learn more about your refrigerator, or to order parts, click here.

Powered by Twitter Tools.

I’ve started using Twitter to post quick appliance repair tips. These are things that don’t quite merit a full-blown blog post here at the site but are still Fun Facts to Know and Tell (FFTKAT). Seems like the ideal use for microblogging. It’s stuff like pointing out a particularly illuminating post at the Samurai Appliance Repair Forum, links to appliance service manuals, appliance recall alerts, and maybe a little personal stuff, too. Take a look at my Twitter page and you’ll see what I mean.

I’ve started using Twitter to post quick appliance repair tips. These are things that don’t quite merit a full-blown blog post here at the site but are still Fun Facts to Know and Tell (FFTKAT). Seems like the ideal use for microblogging. It’s stuff like pointing out a particularly illuminating post at the Samurai Appliance Repair Forum, links to appliance service manuals, appliance recall alerts, and maybe a little personal stuff, too. Take a look at my Twitter page and you’ll see what I mean.

Twitter posts are called “tweets.” (I know, it took me a while to get used to the metrosexual lingo of the web, too. It’s a brave new world!) You can keep up with my tweets as I post ’em by following my Twitter page. And it’s free.

Precaución: ¡Está Caliente!

Powered by Twitter Tools.

Andy wrote:

How do I remove the front panel of a Fisher Paykel DD603SS dish drawer? I’m trying to resolve an F1 error code problem.

Thanks

Ahh, Grasshoppah, this is one of those repair katas that’s so easy it’s sublime. The only tool you need is a pair of needle nose pliers. All is revealed in this sacred parchment from the Appliantology scriptures.

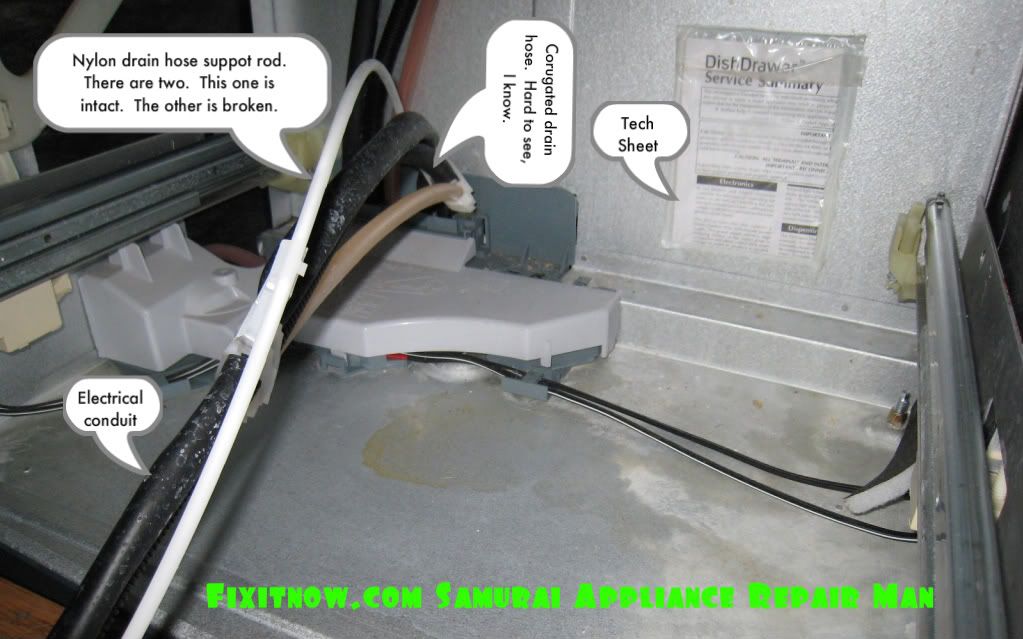

F1 error codes are caused by leaks. On the DD603’s, the most common source of leaks is the drain hose– it gets little splits in it and sprays water inside the dishdrawer compartment during drain. These splits in the drain hose are usually caused by one of the white nylon drain hose support rods breaking. The drain hose itself is just a cheesy plastic corrugated tube that gets easily damaged if it gets bent too much, which is what those nylon support rods are supposed to prevent. Click the thumbnail to see the larger version of the annotated photo wherein all is revealed.

F1 error codes are caused by leaks. On the DD603’s, the most common source of leaks is the drain hose– it gets little splits in it and sprays water inside the dishdrawer compartment during drain. These splits in the drain hose are usually caused by one of the white nylon drain hose support rods breaking. The drain hose itself is just a cheesy plastic corrugated tube that gets easily damaged if it gets bent too much, which is what those nylon support rods are supposed to prevent. Click the thumbnail to see the larger version of the annotated photo wherein all is revealed.

Kanpai! ![]()