A complaint that some new owners of front-loading washers have is that, after a while, the washer starts smelling like moldy socks. In almost every case, with the exception of the known mildew probem with the early model Neptunes, the stench is caused by user error. The Appliantology Masters in the repair forum share some pearls of wisdom for keeping your front-loader smelling schweet.

Author Archives: Samurai Appliance Repair Man

Any Good Dishwashers Today?

Lynne wrote:

I bought a DD603 (dishwasher) today which is to be delivered July 30. Now having found this website I’m scared to death that I should cancel the order for my Fisher Paykel and get something half the price.

Any thoughts?

Thanks

_______________________________

The above message was sent when you were offline, via your Timpani site.Message sent from IP: 67.176.239.94

I’ll answer your question about dishwashers with an astute observation from Samurai Apprentice Grizzly, a brother-at-arms in the ancient craft of Appliantology:

Observation 3. Appliances, like most consumer products, have a sweet spot at which the best long term value can be derived by purchasing items towards the middle of the price scale. Sure don’t see many catastrophically expensive repairs with 600 to 1000 dollar Whirlpool washers. Can’t say the same about Sam’s Club spec GE appliances nor for many uh dem der fancy pants Yourapeen brands.

Amen.

And let us conclude this sermon with a quote from the Samurai Scriptures:

There are no good dishwashers today. They are all gone aside, they are altogether become filthy: there is none that doeth good, no, not one. Yea verily all doth sucketh and fall short of the glory of the Samurai.

— Psamurai Psalms 14:3 (Shogun Tanaka Version)

Right about now you’re nodding smugly to yourself and saying, “Yeah, uh huh, planned obsolescence so the manufacturers can rip us off and line their pockets.” You wanna know the real reason all dishwashers today suck? Go look in the mirror. While you were out clamoring for a new gubmint program to wipe your kid’s bottom or some other inane activity that government has no business getting involved with, the felons in the District of Criminals passed yet another “mandate” requiring that all dishwashers comply with their Energy Star requirements. As if we can just pass a law and, walla!, all our energy problems will be solved. What they’re really saying is that you’re too stupid to be trusted with even having a choice about what type of dishwasher you want: a robust, long-lasting energy hog like yo momma used to have or a limp-wristed bedwetter that uses less energy but that you’ll be fixing or replacing every two to four years. How much energy does that save?

Service Manual for the Kenmore Front Loading Washing Machine

Samurai Appliance Repair Man,

I have a front-loading Kenmore wash machine that is about six years old. The tub would not drain so I replaced the drain pump, the coin trap, and the drain hose. That solved the drain problem but a week later the water was back on the floor. I looked in the parts manual that came with the machine and decided it must be the O-Ring that seals the front and rear shells.

I need a real service manual for this job and the folks at Sears were absolutely worthless in helping me with finding the proper manual. I am searching the web trying to find information on how to approach this job. I am asking for some guidance on validating that this is the most likely cause of the leak and tips for how to approach the repair. Thanks in advance for your time and assistance.

Rick L.

_______________________________

The above message was sent when you were offline, via your Timpani site.Message sent from IP: 65.40.126.96

No model number given but a six year old, Kenmore front-loading washer will be a Friggidaire-built machine. Here’s the service manual for this washer.

You may be further nourished by my uplifting and inspiring sermon on common leak sources in the Frigidaire-built front loading washer.

Lock n’ load, Budrow! ![]()

How to Replace the Clutch in a Whirlpool Direct-Drive Top Loading Washer

One of our fine Master Appliantologists in the repair forum, Tronicsmasta, posted a spiffy photo guide for replacing the clutch in the Whirlpool-built direct-drive washing machine and it’s just aching for the furtive caress of your bulging eyeballs. ![]()

Parts you may need when you embark on this repair adventure:

– Brake and Basket Drive Tube Kit

– Gearcase

(This machine is also sold under the Kenmore brand.)

Haiku for Installing a New Compressor in a Refrigerator: A Song of Degrees

![]()

Replace compressor,

braze with silver then recharge.

One, two, git ‘er done.

(More haikus for appliance repair.)

Tactical Weapons You’ll Need for This Job

Black Max Dual Brass AC Manifold for R-12 & R-134a

MAPP Gas & Propane Self-Lighting Hand Torch

Midget tubing Cutter 1/8″ to 5/8″

If you’ve never, ever done sealed system work before but would like to learn, this sealed system how-to DVD from Frigidaire is a must-have addition to your technical library.

How to Test the Electrical Components in the Whirlpool Duet Washer

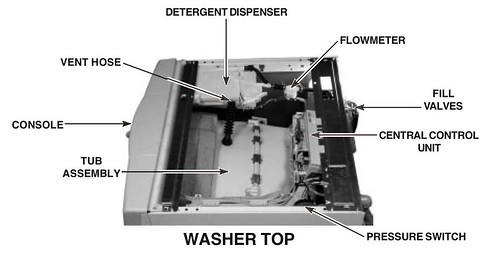

This washer also masquerades under the Kenwhore label but it’s the same machine. One of the nice things about this washing machine is that you can test all the main electrical components right at the Central Control Unit (CCU), conveniently located under the top panel, in back. Looky here:

These pages will help you find your way around inside there and clue you in to what type of measurements you need to do. BTW, the service manual for this washer is the best $25 you’ll ever spend; come git you one.

Once you figger out what’s wrong, the Samurai recommends that you buy the parts you need ratcheer. You’ll get ’em fast and you can return any part for any reason.

Frigidaire-built Kenmore Front-Loading Washer Won’t Spin

Common problem with this otherwise tragically flawed washer: it will tumble and pump out the water in the tub, but it will not spin. Usually, the problem is the speed control board. However, in accordance with the Ichiban Law of the Prophecy, you should use your meter and do a few tests to prove that the board is bad.

“But, wise and besotted Samurai, what tests are those of which you utter with slurring speech and stumbling gait?”

The ones that are printed on your washer’s tech sheet, Slick, which you’ll find behind the kickplate.

This topic in the repair forum links you to a service manual for this washer and, oh, so much more. Come ye and bask in the ancient wisdom of Fixite Do with the Sublime Masters of Appliantology at the Samurai Appliance Repair Forums.

To learn more about your washing machine, or to order parts, click here.

Whirlpool Duet Sport Dryer: Gut Check

The Whirlpool Duet Sport is skulking around the Ameedican market. The one schweet thing about this dryer is that you can get to all the guts via the top or front panels– no need to pull it out from the wall in violation of the 10th Law of the Prophecy.

Disassembly follows the same procedure as for the Whirlpool-built dryer with the lint filter in the door, see this page.

BONUS: Here’s a field report from Sublime Master of Appliantology Nickfixit on a recent service call he did on one of these dryers:

Hi Guys,

By some stroke of luck I got to work on a Whirlpool yesterday. It was a Duet Sport Dryer about 3 months old. The drum belt was broken, and I was lucky enough to have it on the truck.

My first observation is that it’s sort of a pain to install. I had to take the console and front off to do it.

The second issue is the spring on the idler pulley. I could not believe how strong that idler pulley spring was. It takes both hands and major strength just to push it back enough to get the belt installed. I’m serious, it really is monstrously strong. I’d guess that spring is at least 5 times stronger than the regular Duet.

I’ll bet if you left 100 new ones in the box for 6 months, you would find most had broken belts just from the spring pressure on the idler.

I’ll bet we will be doing a lot of these belt jobs in the near future.

Nick

How to Re-Calibrate the KitchenAid Dual-Fuel Ranges

This tech tidbit applies to the K/A dual-fuel ranges with steam, models KDRP707RSS00, KDRP707RSS01, KDRP767RSS00, or KDRP767RSS01. If you’re having temperature control problems with this range, here’s whatcha need to do:

1. Foist, make sure the oven control is off.

2. Next, turn the Selector knob to Bake, Convection Roast or Convection Bake. For your calibrating pleasure, calibrating in Bake will not affect Convection Roast or Convection Bake temperatures. To ensure that this little chore is comfortably tedious for you, they set it up so that you gotta calibrate each cooking mode separately.

3. Press and hold the CANCEL key; the display will show STOP. While still holding the CANCEL key, press and hold the ENTER key until the display shows a flashing “0.”

4. Now turn the set knob to increase or decrease the temperature in increments of 5°F. You can go a maximum of 30°F either up or down. A minus sign means the oven will be cooler by the displayed amount. The absence of a sign means the oven will be warmer by the displayed amount.

5. Press the ENTER key to accept the change and STOP will be displayed.

6. Turn the Selector knob back to “Reset” to end this joyous calibration procedure.

Appliance Deconstruction Techniques Illustrated

Appliance deconstruction is a technique sometimes used in the ancient martial art of Fixite Do. Since deconstruction is terminal for the appliance, it is only used as a last resort.

An Apprentice Appliantologist at the repair forums posted a nice demonstration of appliance deconstruction using the Impact Technique. One thing to notice in this demonstration is that the washer has an electronic user interface board, which has been a troublemaker on this model and which was the problem in this case. It’s not surprising that it ended up in deconstruction since this washer model violates the 5th Law of the Prophecy.

The Percussion Technique is another method which is quicker and more thorough but requires a larger work area and some specialized appliance deconstruction tools.

Adventures of a New Appliance Technician

Appliance Tech, Grizzly, a new brother-at-arms in the ancient martial art of Fixite Do, shared some of his more vivid experiences and observations of his first few months of practicing the craft of Appliantology.

Interesting (well, not really) observations I’ve made in the larval stage of my appliantology career. Five months may not be long enough to have a truly mature and time tested opinion on stuff, but here goes anyway….

Observation 1. As a profession, servicers are treated by customers with somewhat more suspicion than I was expecting. I’d say the average customer is more guarded with me than they would be with, say, a census taker or perhaps a meter reader. Having said that, I haven’t received much in the way of the immediate cold shoulder and scornful treatment with which, say, an ambulance chasing trial attorney has likely become used to. I’m thinking a spectral analysis of professions would peg appliance servicers several notches up the scale from car salesman, but lagging a few rungs south of dental hygienists.

Observation 2. The plural form of servicer is not present in the OpenOffice.org spell check, whereas the singular form is.

Observation 3. Appliances, like most consumer products, have a sweet spot at which the best long term value can be derived by purchasing items towards the middle of the price scale. Sure don’t see many catastrophically expensive repairs with 600 to 1000 dollar Whirlpool washers. Can’t say the same about Sam’s Club spec GE appliances nor for many uh dem der fancy pants Yourapeen brands.

Observation 1 reprise. Some customers seem to have an over simplified view of the profession and are pre conditioned to think that anyone who works with their hands must have a Forest Gump level IQ. Here’s some quotes I’ve heard so far:

From a passively aggressive/somewhat condescending dishwasher customer, I think she must have thought she was talking to her 8 year old: “now, I know the dishwasher water goes into my garbage disposal, so if you need to get under the sink to look at it, you will need to be careful, there are c-h-e-m-i-c-a-l-s down there, like Comet and Dawn, those can harm you, so please be careful”. I felt like playing along by dawning a puzzled expression and telling her “Oh, yessum mam, dey done told us in skoo dat Comet ain’t duh same ting as sugar. You can’t eat Comet, you can only clean stuff wit it. But sugar, dats ok to eat, my momma puts sugar on her grits and she’s as fit as a possum. My cousin Billy once ate a whole can of Comet, and his pee smelled good for a month, but I ain’t gonna eat none of your Comet, I like tha yellow smell my pee has better anyhow.”

Or how about this quote from a dryer customer, “what do you mean you need the wiring diagram? I read my owner’s manual this morning, and it doesn’t say anything about wiring diagrams, so you must be trying to make this more difficult than it needs to be so you can charge me more”.

Observation 4. This work involves a perfect blend of both mental and physical skill. After sitting at a desk all day for eight years programming mainframes, the actual act of getting to move about is quite a refreshing change, but the one thing about programming that I actually enjoyed (solving logical problems) is present here too! Very similar approach to the problem solving and analysis, just a different subject matter.

Observation 5. This work is freaking fun! For the first time in years, I no longer dread going to work each day. Hell, when 5:30 comes around, most days, I don’t want to leave the shop.

How to Replace the Mounting Stem/Seal and Tub Bearing in a Maytag Dependable Care Washer

This washer is an oldie but goodie, manufactured by Maytag back in the days when Maytag earned a reputation for quality and dependability (unlike the junk being cranked out today with a Maytag label on it).

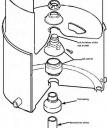

A sure sign that you need to do this repair on your trusty old Maytag is if you see water leaking from the center of the tub onto the transmission. To check this, you’ll need to remove the front panel. Other indications may be a tub that’s reluctant to spin (or burns belts) or makes a ghostly howling noise during spin. The diagram shown here to the right will explain what’s happening (click the pic for a larger view).

A sure sign that you need to do this repair on your trusty old Maytag is if you see water leaking from the center of the tub onto the transmission. To check this, you’ll need to remove the front panel. Other indications may be a tub that’s reluctant to spin (or burns belts) or makes a ghostly howling noise during spin. The diagram shown here to the right will explain what’s happening (click the pic for a larger view).

You may be thinking, “Oh, but it’s so old, I’ll just buy a new washer and get another 20 years out of it.” Oh, feckless grasshopper, you would be in for a rude awakening.

OK, proceeding on the assumption that you are one of the thinking grasshoppers and not one of the brainless masses being manipulated by the purdy pictures of shiny new appliances dangled in front of your nose by the savvy marketing teams of the manufacturers, let’s get into the nuts and bolts, so to speak, of doing this repair.

I. Essential Tools

– Spanner wrench (to remove the inner basket).

– Sockets: 1/4″, 5/16″, 3/8″, and 1/2″

– Straight-slot screwdriver

– Allen wrench or torx set (depending on the set screw used on the replacement part).

– Beer. Lots of beer. About four, 16 oz. mugs, to be exact.

II. Required Parts

– Mounting Stem and Seal Kit

– Tub Bearing Repair Kit

III. The Procedure

1. Unplug washer and Remove two Philips head screws holding front panel in ( newer models have clips on the bottom and no screws )

2. Remove front panel, lift panel from sides, has two “tabs” on top

3. Remove two 3/8ths hex head screws holding top down

4. Lift up top, it’s somewhat hinged, careful lid doesn’t smash against wall or pipes

5. Disconnect water tube on left side to top cover

6. loosen the two screws on the steel band… straight or 5/16th ( newer washers have a plastic tank cover, pry out the tabs and lift up to remove the plastic tank cover )

7. gently but forcefully remove the top cover

8. careful not to bend the band or cut the gasket

9. *remove the agitator by grasping firmly and pulling up towards your chin, carefully!

*( many have 1/4 hex head screw on agitator, down the side near the base, older ones have a rubber ring on transmission shaft )10.using a hammer and your spanner wrench remove or cut off the spanner nut, it is a left hand thread so it must come off clockwise, careful not to chip the tub

11. remove the inner tub,, it’s heavy with the concrete counter balance

12. take the Allen wrench screw (or torx) out of the mount stem ( see one of the 4 dimples for the set screw )

13. using your hammer and spanner wrench take the mount stem off, mount stem is a left hand thread so it must come off clockwise

14. now grasp the seal and remove, careful you can slip

15. put a 1/2″ socket on the nut on the front and 1/2″ box wrench or adjustable wrench on the inside bolt, and loosen using the socket on the outside, but not remove entirely the front nut

16. then using the same two tools remove the left and right bolts and nuts and lock nuts and plate, noticing the fiber washer

17. then remove the front one

18. remove tub to pump top hose clamp and pull off up 1/2 of that hose, now work the outer tub loose and lift up but not out entirely

19. remove the pressure hose on your rear right side

20. take out the tub

21. stomp (using your foot) out the tub bearing housing from inside the outer tub

22. remove the “metal sleeve collar” on the transmission shaft

22A. you’re half started

23. turn the outer drum over

24. take the new tub bearing and “stomp” it into the outer tank…flush, take your time and double/triple check yourself on these steps, (takes less time to recheck and verify than to tear down and start over)

25. put the new collar over the transmission

26. put the outer tub back on and reattach the pressure hose and pump hose

27. line up the front hole and put the front (short) bolt in, making sure you have the fiber washer on the outside of the tub

28. put the rectangular flat washer on, then the lock washer and the nut by hand…

thread it on a couple of turns but leave loose29. put the right and left bolts and stuff on, tighten well

30. tighten up the front one

31. Put the seal on next, careful not to tear the seal, but it needs to be all the way down. One side has a special edge of carbon or something like that and that needs to be UP towards you. Sometimes taking a little bit of liquid laundry detergent and lining the inside bottom lip of the seal with it can help with the installation of the seal onto the tank.

32. take the torx screw out of the new mount stem, and screw down the stem mount, tighten with spanner wrench ( don’t over tighten! ), install the torx screw

33. put the inner tub on

34. check the spacing around the top of the inner tub (making sure that the tub is not listing one way or another)

35. put the metal cover on and spanner nut

36. put the top cover on and push it all the way down

37. check and clean the gasket and put it back on

38. put the clamp back on over the gasket

39. tighten to a moderately firm but not tight setting

40. carefully with a long straight screwdriver pry up the top part, bit by bit

run your fingers around the clamp to make sure the gasket didn’t pop up41. when you think you have a good position, take your index finger and on the inside put it between the top cover and top of the inner basket and make sure you have this space all round so that the inner basket doesn’t rub against the top cover

42. tighten the clamp

43. reinstall the hose from the injector to the top cover

44. plug unit back in and turn to spin

45. let it spin for a couple of minutes

46. turn timer to fill and put water in

47. water test before securing top and reinstalling front panel

To learn more about your washing machine, or to order parts, click here.

Name That Part!

Yes, boyz and beanz, it’s time for everyone’s favorite game, Name That Part! If you can guess the part shown here in the thumbnail pic (click it for a bigger picture), then you’ll get a special treat from the Samurai. Here’s a hint: it comes from a Whirlpool-built (Kenmore-branded) top-loading, direct drive washing machine.

Yes, boyz and beanz, it’s time for everyone’s favorite game, Name That Part! If you can guess the part shown here in the thumbnail pic (click it for a bigger picture), then you’ll get a special treat from the Samurai. Here’s a hint: it comes from a Whirlpool-built (Kenmore-branded) top-loading, direct drive washing machine.

Give up? OK, click here for the answer.

GE Recalls 2.5 Million Dishwashers

Yet another appliance recall notice *yawn*.

According to CPSC, this recall is due to a faulty liquid rinse-aid dispenser. Apparently, the dispenser can leak rinse aid onto the dishwasher’s internal wiring which can cause an electrical short and overheating, posing a fire hazard to consumers. Read the sordid details ratcheer.

I wonder how much of this is just hype. OK, how many of you have actually had your dishwasher catch fire because of this? Raise your hands. No one? Yep, sounds like yet another gubmint make-work project to me.

Something else verrry interestink about this recall is that it sounds suspiciously like the recently-announced Maytag and Jenn-Air dishwasher recall, which was for the exact same reason!

Hmmm… even though all the manufacturers are in bed with each other, seems like we’re the ones getting screwed. ![]()

Getting to the Lid Switch in a Kenmore Top-Loading Washer

what is the best way to get to the lid switch on a kennmore washer, model # 110.28812790. It looks as if I need to remove the whole outer shell.

_______________________________

The above message was sent when you were offline, via your Timpani site.Message sent from IP: 12.24.236.162

You are correctum! The technique is illustrated below. If you need more verbose instructions, come hither.

To learn more about your washing machine, or to order parts, click here.