From: Janice

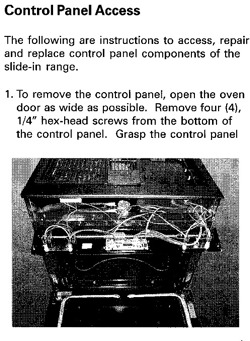

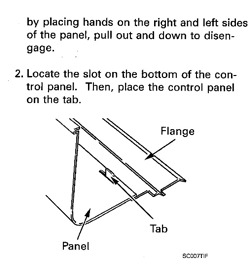

Subject: When you were offline (via LivePerson)

I am renting a condo which has a Kenmore stackable washer & dryer, model no. 88752. The dryer does not dryer my clothes in 40 minutes, I end up having to run the load another 30-40 min. And I am not overstuffing the dryer. I have cleaned the lint filter, what else could be the problem. Meanwhile, my elec. bill is climbing, I have resorted to an old-fashioned clothes line which actually works well in the Florida sunshine but not always practicable on rainy days. Plus I am a working gal. Please help. My landlord is sending a repairman over but I have a feeling he will say it’s heating okay. Never gets super hot. What do you think?

_______________________________

The above message was sent when you were offline, via your Timpani site.

Message sent from IP: 67.132.198.254

This is a classic case of a bad dryer vent.

Let’s start with a quick, simple review of how dryers work. Dryers get clothes dry by doing two things: 1) heating them up so the water can evaporate and 2) moving lots of air to get rid of that evaporated water so that more can evaporate.

See, you can heat the clothes all day long but if the air above those clothes is already saturated with water vapor (i.e., at 100% relative humidity), then all you’re gonna have is warm, wet clothes because the air can’t hold anymore water vapor. Now you begin to understand why the dryer vent is so crucial… and so misunderstood.

“Yeah, nice theory, Samurai Poindexter, but what does this mean about MY dryer; I, ME, MINE!”

Oh, take a pill already. Pull your stacked dryer monstrosity out from the wall and look behind there. I’ll bet you’ll find that collapsible, spiral wound duct material for your dryer vent. What happens to that material when you push the dryer back against the wall? Right: it gets crushed. And what does that do the air flow through the dryer? Hey, is that a light bulb I just saw go on over your head or is it the light of my own brilliance?

With this enlightened understanding of how dryers work, you are ready to grok the Ultimate Dryer Venting Guide.

![]()